Change the plastic properties and the resulting product might have serious issues or the mold can simply no longer be used. To determine the thickness of a plastic bag or its gauge you need to find its mil score.

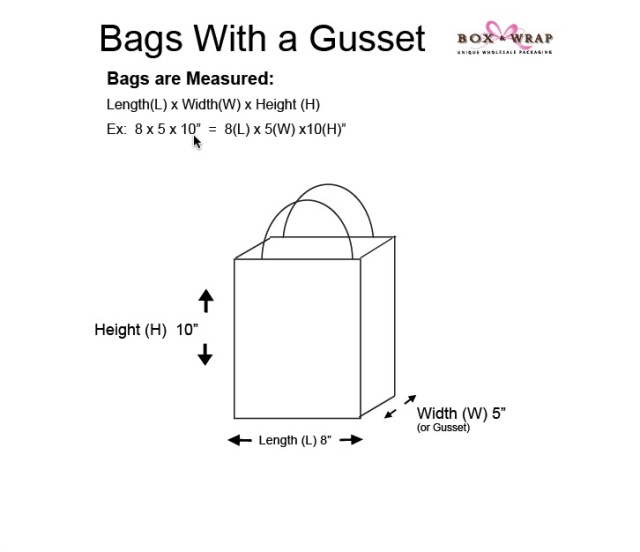

Measuring Guide Shopping Bags With Handle Box And Wrap

The strongest type of plastic bag is made of HDPE or high density polyethylene.

. Plastic Bag Quality Test Defines Their Market Use. Paper bag is made by simply folding the paper and bonding it with the adhesives. Collect the plastic bags.

IMADA offers the dedicated testing system such as the following configuration which is utilized in quality control and RD. This website uses cookies to ensure you get the best experience on our website. Cut the plastic bag into a 300mm by 200mm piece.

In fact different types of poly bags are developed just for their strength properties. Strength - can be thought about in many ways. It enables testing according to the corresponding part of JIS Z1711.

And try to lift it on the handle of the. A mold is made for 1 type of plastic polymer. Cut the heat-sealed part of plastic bag and grip it with 2pcs attachment to test the heat seal strength.

The plastic properties were chosen to fit with the intended use and use environment of the finished product. Cut out the three rectangular pieces of plastic. Take any samples on the side back top or bottom of the plastic film packaging bag perpendicular to the heat-sealing part and use them as heat-sealing samples on the side back top or bottom of the packaging bag 10 samples are cut for each part At least.

To determine the tensile strength of plastic bag handle grip a plastic bag handle with dedicated grips and pull it to break with a force gauge. But as an end user you can simply load the. When the pressure reachs to the climax it will stay for a period of time and check if the package breaks.

A typical seal strength plot is shown in Figure 1. These marks will be used to measure the amount of deformation or strain. On each of the rectangles draw two lines across the 3cm width - one 5cm above and one.

Answer 1 of 3. Try to fill each plastic bag with some heavy material such as groceries trash sand and rocks. Collect different kinds of plastic bags in different stores.

Dart Impact Testers To test the Impact Resistance of Plastic Films. Independent variable The width of the plastic bag. About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy Safety How YouTube works Test new features Press Copyright Contact us Creators.

In this test a predefined load is made to fall on the packet using a missile style dart. When the plastic pouch is intended for liquid products such as juice olive oil washing chemicals liquid fertilizer water etc pressure test is a reliable way to check its strength. When the pressure reaches the expected.

Up to 24 cash back Method. Changes to the material that determine thickness and strength occur during the. The methods to determine the heat sealing strength of plastic packaging bags are.

Thicker bags are typically stronger than thinner bags of the same material. To lead the line one must ensure the quality standards. The experiment below is one which you could try in the lab and is similar to the method used by real scientists to test the strength of plastic bags.

In this activity strength will be measured either as the load required to stretch and break a piece of material or the puncture force to push an object into or through that material. Also try out a number of plastic trash bags preferably the ones you have either used in the past or plan on testing to see which are best to use. A jaw moving at a defined constant rate 1012 inmin pulls the seal apart while measuring resistance during seal separation.

Different widths of plastic bags will affect how much mass they can carry. We will fill certain volume of water into the plastic package and apply certain pressure from the top. Plastic bags are the most used form of carrying bags in our nation.

Lay it out flat and carefully draw three 3cm x 15 cm rectangles. Heat Seal Strength Test of Plastic Bags. When we talk about carrying bags the best would be those who can carry a lot of stuff for a longer.

Plastic bags are used to carry items and to dispose of trash. The strength of a plastic bag is determined by its material and thickness. Some of the tests that need to be performed to assess the quality of paper bag.

To determine the tensile strength of plastic bag handle grip a plastic bag handle with dedicated grips and pull it to break with a force gauge. Place the hanger onto the bottom hook. Obtain a plastic shopping bag.

This can be measured with a ruler and cut with scissors. Select the plastic bags from all the grocery stores you visit to compare strength. For the below test we are going to take 20 litre plastic cheertainer.

This test is particularly applicable to. Plastics ReMSTEP Deakin University Key ideas Force - a push or a pull. BS EN ISO 527 Tensile propertiesTest conditions for molding and extrusion plastics.

Dart impact strength determines the resistance of the plastic films against the free falling of blunt object on the packet. So a peel strength tester is used to analyse the force required to fail the adhesion. Collect items to test.

There are several reasons why you need to stay on top of this. The type of plastic bag that is the strongest will depend on the way the plastic is made. Secure the strip into the material clamps.

Anti-pressure test comes up with a certain pressure applied on the chear cheertainer package which is usually filled with water. Cut each sample. On each of the rectangles draw two lines across the 3cm width - one 5cm above and one below the center.

Measure and cut a 70mm by 200mm strip. Page 2 Sample Answers Materials Testing. The rising demand for the manufacturers can build a challenge for them.

Add 100g masses at a time and measure the maximum mass that the strip can hold. Chapter 2 Activity Durability Testing of Plastic bags Ideas for Method How can we test the strength of plastic bags. The most common way to measure the yield strength of plastics is with a tensile test.

It is widely used for quality control and RD. Tensile seal-strength testing ASTM F88 uses a defined width sample 254 mm or 1 in of the package seal perimeter. If the packet withstands the test it is declared as pass.

Repeat with 60mm 50mm 40mm 30mm 20mm and 10mm strips.

Pangaia S Compostable Packages By Tipa Your Product Stays Protected While It S On It Clothing Packaging Branding Design Packaging Packaging Design Inspiration

300pcs 12x15 5 30cm40cm Custom Plastic Bags High Etsy Clothes Plastic Clothing Packaging Custom Plastic Bags

Custom Shop Bags Custom Plastic Zipper Bags Shop Bag With Logo Jewelry Bags Custom Bag For Your Business With Logo Zipper Bags Clothes Plastic Bags

Plastic Packaging S Photo Gallery Clothinglabels Cn Plastic Packaging Design Clothing Packaging Creative Packaging Design

Fused Plastic Shopping Bag Shvejnye Idei

100 Custom Plastic Bags 6x8 Custom Zipper Bags Frosted Etsy Custom Plastic Bags Zipper Bags Plastic Bag Packaging

Plastic Packaging S Photo Gallery Clothinglabels Cn Packaging Plastic Packaging Packaging Design

100 Custom Frosted Zipper Bags Clear Zip Lock Bag High Quality Cloth In 2022 Zipper Bags Clothing Packaging Plastic Packaging Design

0 comments

Post a Comment